Product Description

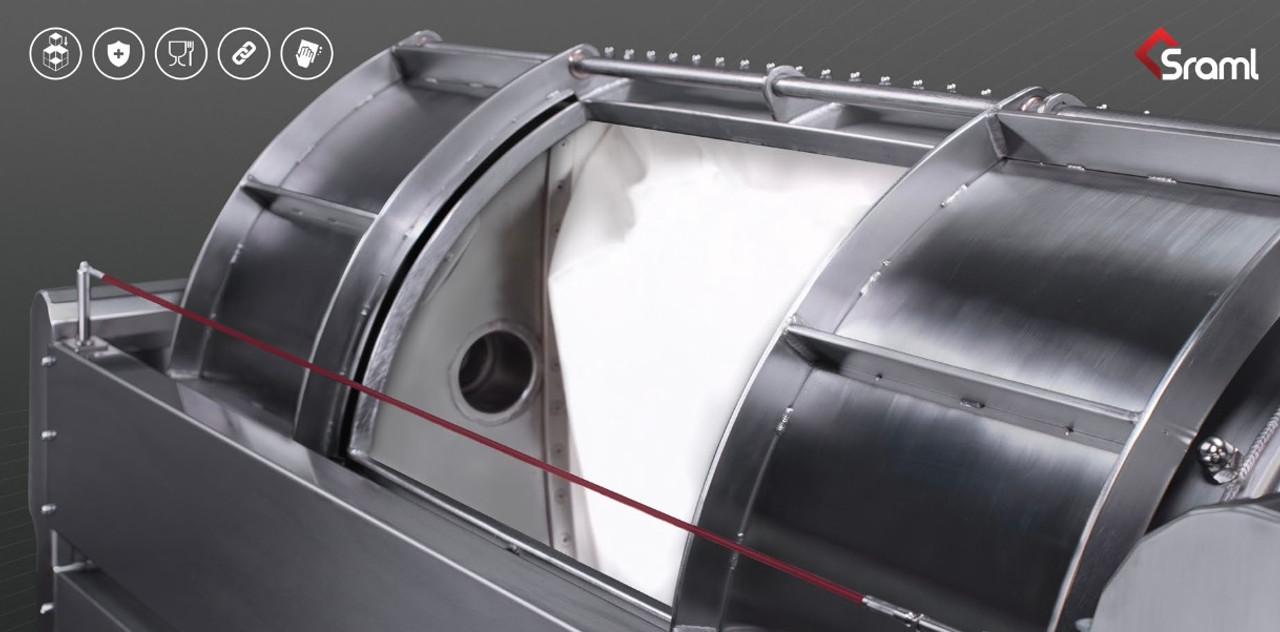

The SRAML VPe and VP Series of Pneumatic Membrane Presses combine the simplicity of design and use with innovation for the ultimate performance. Equipped with a number of programmable pressing cycles and improved drain surface to maximize juice yields, the SRAML line of pneumatic presses offer the ultimate addition to your winery. Gentle pressing of the grape mass and significant reduction of processing time is key to achieve the quality of wine you have been aiming for.

Available in sizes from 500 to 2100 liter, the plug-and-play VPe series stands for user-friendly operations and best price-performance ratio, offering a vast array of upgrade possibilities to create the ideal press for your production demands.

VP Eco pneumatic press features include:

- Available from 500L to 21HL

- AE Automation controls

- User-friendly 4.3" PLC touch screen with (12) pre-programmed pressing cycles

- Additional (8) channels for custom programming

- Quiet fan for fast airflow to +.2bar

- Ultra-quiet Becker compressor

- Large mobile juice collection tray with sieve (screening) on the outlet

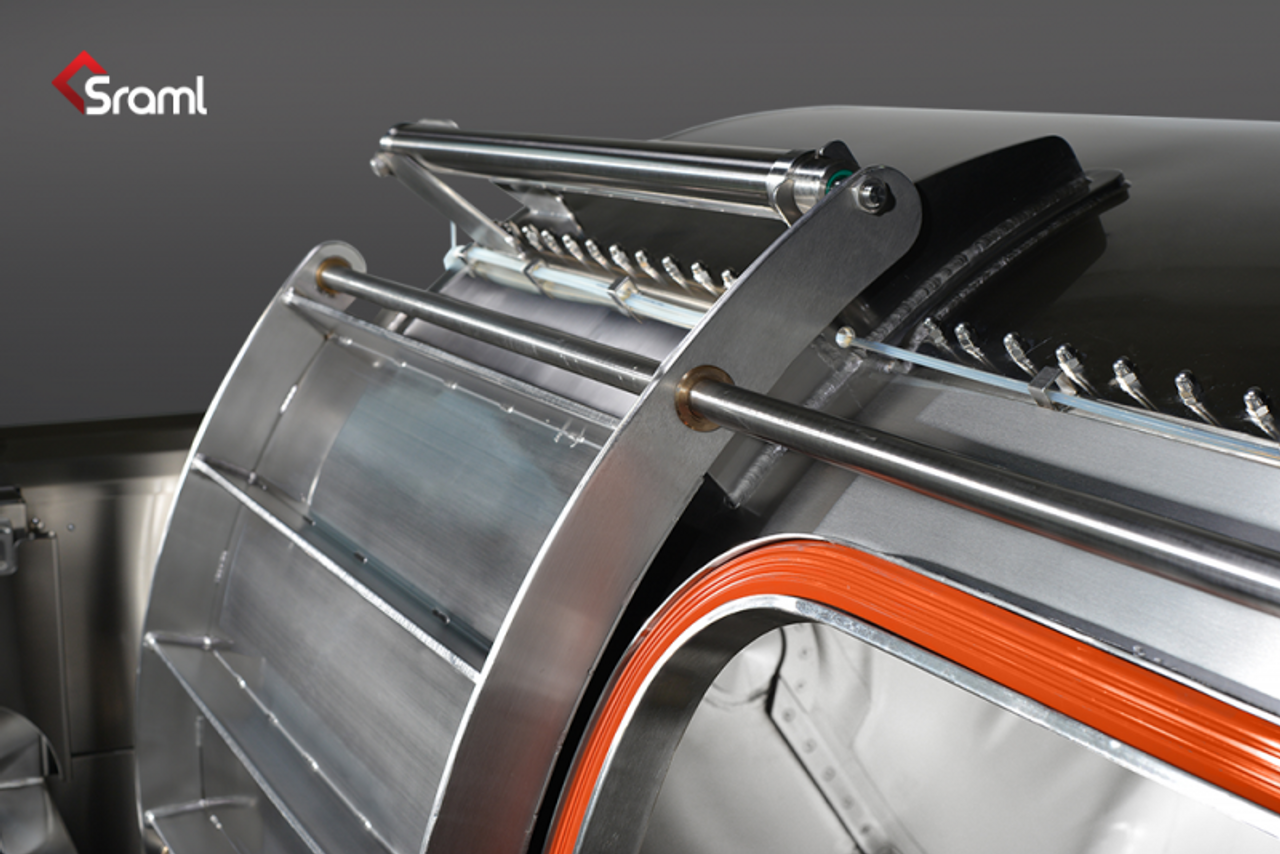

- Large double sliding doors (8HL and larger) to provide easy interior access for loading, unloading and cleaning

- OPEN or CLOSED cage pressing system

AVAILABLE OPTIONS

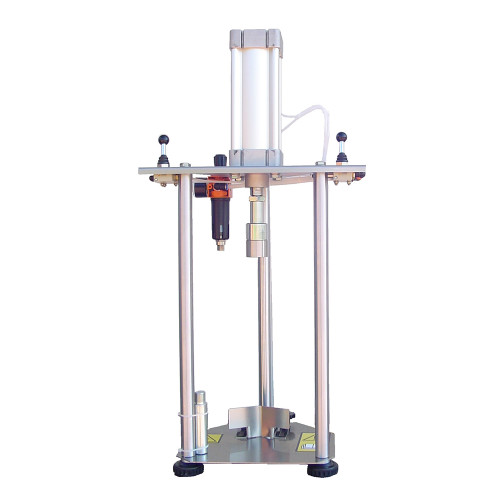

- Axial loading valve

- Axial loading valve with pressure sensor

- Non-perforated doors for maceration

- Collection tank level switch

- Sliding juice tray

- Single-phase wiring

- Leg extensions

- Staircase and platform

- Cleaning option

The VP (standard) line of presses range in size from 26HL to 150HL and are intended for wineries processing larger quantities of grapes. Standard features on the VP line include axial valve loading capability, a 7" touchscreen with (8) programs; (4) programs with non-modifiable parameters, (2) programs with non-modifiable parameters, (1) program for maceration and (1) program for axial loading and large double doorways. Despite a higher level of complexity, the VP line of SRAML presses are as user-friendly as the VPe line.

AVAILABLE OPTIONS

- Axial loading valve with pressure sensor

- Cabled remote control

- Staircase and platform

- Inflatable water-tight doorway seals

- Cooling/heating jacket on the cylinder

- Single central drain outlet

- Feed hopper

- Non-perforated doors for maceration

- Drainage channels on hinges

- Pneumatic door open-close mechanism

- Collection tank level switch

- Sliding juice tray

- Single-phase (220V) wiring

- Leg extensions

- Cleaning option